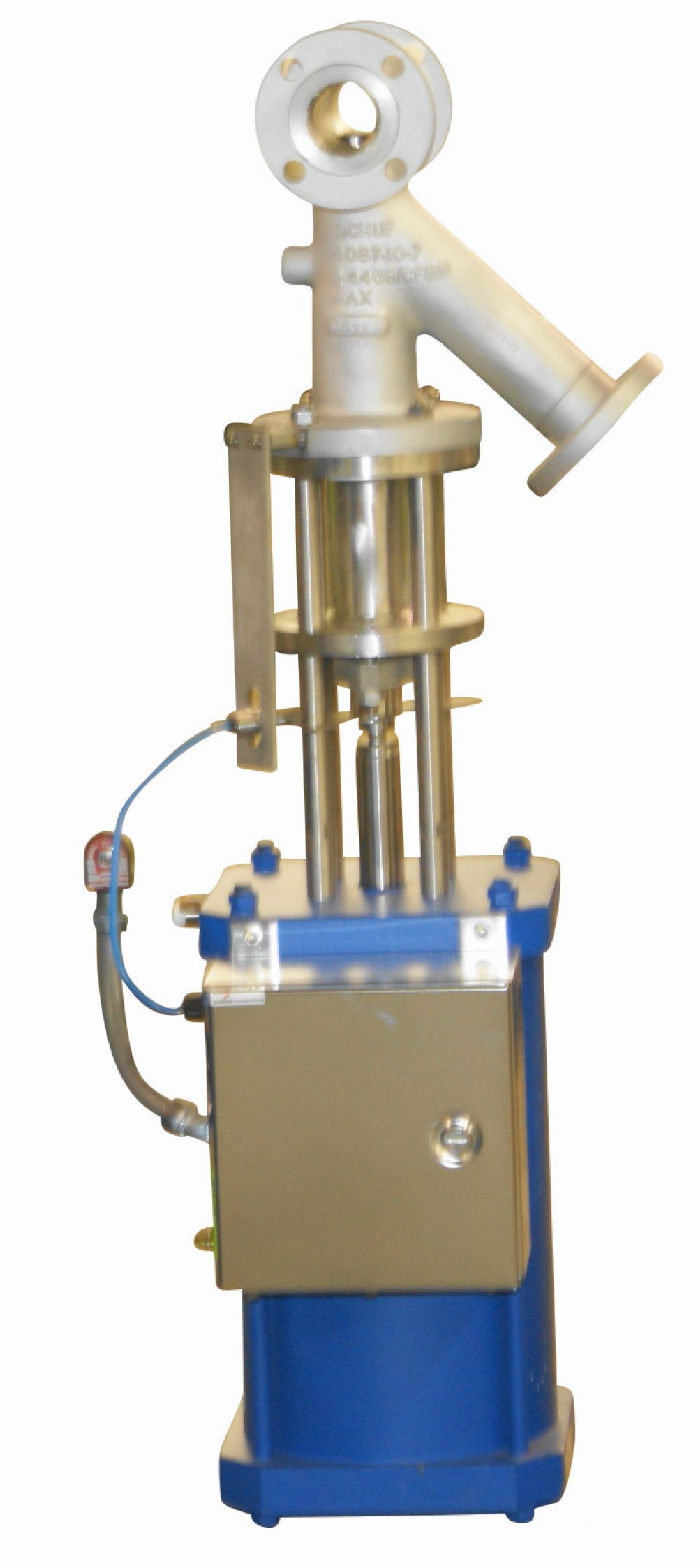

Ram Seal Bottom Outlet Valves

The primary application of the Ram-Seal flush bottom outlet valve is used to quickly drain fluids from tanks or reactors. Their use has been been expanded into areas with high viscous fluids, gases, slurries, and powders. In addition to draining they can be used in reverse flow, injection and sampling applications and areas where positive shut-off (zero leakage) are required.

Ram-Seal Valves for TDI process

Ram-Seal Valves for TDI process Ram-Seal Valve - Characteristics

The ram-seal drain valve is a free flowing, full opening valve design that offers bubble tight Class VI sealing characteristics that ensures positive shut off to process. In laboratory tests Ram-Seal valves have exceeded all Class requirements and delivered positive shut off over several hours of testing. The design ensures:

- Clog Free Performance - automatic rodding on every stroke

- Flow in either direction - can be used to drain or inject media without damage to the sealing mechanism

- High Cv - 45 degree branch assures rapid drainage, unobstructed by valve stems, restricted ports or unnecessary change in flow direction

- No leaks - achievement of absolute zero leakage

- Extended seal life - as the seal is not in the flow path

- Diverse Low emissions packing designs are available

This unique and superior performance explains why this bottom outlet valve is widely used in the Chemical and Petrochemical industries in diverse applications. This includes most polymer applications...polyester, polyethylene, HDPE, PTA, Polystyrene, Catalysts, DMT, TDI, MDI to name a few.

Their reliable performance and dependable sealing means that they are also used in severe services including radioactive waste and mineral processing applications.

The Ram Seal valve is a flush bottom outlet valve with a standard 45 degree outlet angle that optimises flow and Cv. In addition to zero leakage, Fetterolf Ram Seal valves provide clog free drainage in viscous, slurry or abrasive service. The stem is swallowed by the ram, thus ensuring a more compact build. The ram cleans the valve body and nozzle with every stroke.

The Ram Seal comes with a deep stuffing box or gland that assures no leakage to atmosphere as standard. Many stuffing box designs or packing arrangements are available to meet specific media or low emissions requirements.

A manual actuator is shown, but the Ram-Seal can be provided with pneumatic, air motor, hydraulic or electric actuation.

Fetterolf piston drain valves are available with several basic design options:

- ½ inch (DN 15) to 24 inch (DN 600)

- ASME 150# (PN10) to ASME 2500# (PN 200) as

standard

standard - 45, 60, or 90 degree branch outlet angle

- Custom adapted to fit vessel pad - dead space free

- LeakTight Shut-Off to Class V or Class VI

- Adjustable stuffing box seal to atmosphere

- Extended body or plunger

- Electric, hydraulic, pneumatic or manual

actuation

Options

- Jacketed Bodies - to ensure the optimum temperature is maintained at all times

- Flushing connections - to enable the valve body to be flushed during or after operation

- Integral Extended Body - an extended body to fill the void within the connection piece or nozzle

- Extended Plunger - an extended plunger to fill the nozzle or connection piece void

- Alternative sealing materials

- TA Luft Packing and other Low Emission Packing to meet almost any standard

- Contoured plungers to ensure smooth flow when installed in a pipeline or loop reactor

- Integral core pipe construction

- Integrated sampling valves - an independent sampling valve can be integrated to take samples of the draining media

- A multitude of sensors can be installed in the plunger to measure temperature, viscosity

The Ram Seal features and design lead to many advantages:

- Clog free performance; automatic rodding on every stroke

- Using extended body, the plunger is flush with the ID of the vessel or pipeline

- Obstruction free flow; no valve stem in product flow

- Reverse flow capability; retracting seal ring avoids impingement and abrasion by product

- Leak free design

- Extended plunger option; permits ramming to or beyond flush surface of pipe or vessel

- Full ACME stem threads; diameter and pitch selected to prevent stem back-off under high system pressure or vibration

Ram Seal - Sample Reference

Customers

| Customer | Customer |

BASF | Hatch |

BP | Invista |

Barrick Gold | Jiangsu Hengli |

Braskem | Monsanto |

Chevron Phillips | PT Styron |

| Chemtex | Reliance |

| Dow Chemical | Saudi Polymers |

| Ebara Nuclear | Sabic |

| Exxon | Saudi Aramco |

| Formosa Chemicals | Thai Polypropylene |

The Ram-Seal Principle

The Ram-Seal® valve works by having a plunger (Ram) operating within a cylinder. When the valve is closed the plunger (Ram) occupies the entire inner bore in the valve body leaving minimal space for particles to collect.

The primary sealing is provided by a resilient seal ring mounted on the Ram. It travels with the Ram throughout the stroke. It seals when the seal ring receives a thrust force from a compression ring as the Ram moves to the closed position. The seal ring is expanded into a wide band seal against the surface of the sealing barrel (Seat) and against the Ram.

In the open position the seal ring is retracted out of the flow stream hereby being protected from abusive forces from flow and velocity. The wear on the seal ring is minimized as the sealing contact occurs only while the Ram travels the short distance of the seating area