Rod-Seal Bottom Outlet Valves

The Rod Seal drain valve is designed and built to eliminate the typical problems of conventional valves in severe service applications. The Seatless Sealing principle plus Superclosure thrust loading provides the basis of the Rod-Seal difference. The valve has been proven in sampling, purging, or draining highly viscous media, polymers, abrasive slurries and powders.

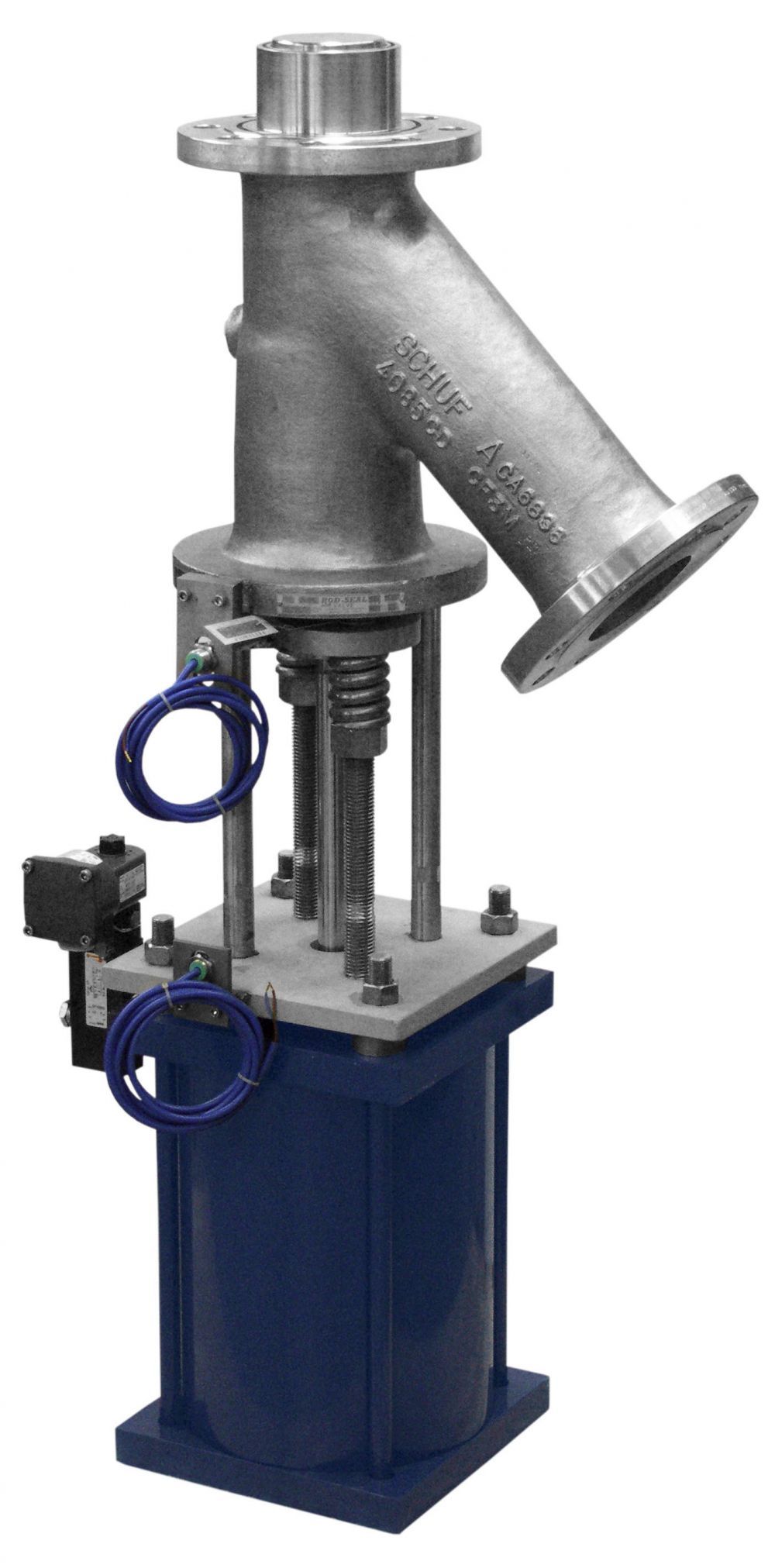

10 inch ASME 300# Reactor drain valve

10 inch ASME 300# Reactor drain valve Rod-Seal Valve

The Rod-Seal bottom outlet valve is designed to be fast acting, with an obstruction free flow. The pressure sleeve design means that there is no seat for any material to collect or contaminate later batches. The Super Closure feature (live loading sealing elements with springs) ensuring a tight shut-off to process and to atmosphere and the fully hardened, diamond polished plunger extends packing life.

The design assures:

- Absolute positive shut off - no leakage of the medium to process

- No leakage to atmosphere - the deep stuffing box has both live loaded packing as well as automatic self adjustment through the super closure mechanism

- The seatless concept which is delivered through the use of an inner guide sleeve means that there are no dead spaces for medium to collect, that could either impede the operation of the valve or contaminate the media

The Rod-Seal Valve comprises of 5 key elements - the valve body, the Ram or piston, the pressure sleeve, the stuffing box and a series of packing and sealing rings towards the bottom and at the top of the valve. The unique interplay between these parts makes the Rod-Seal seatless valve the ultimate valve for slurries or medium with a high degree of entrained particles.

Operation

Upon closing the plunger advances through the bore, effectively rodding material from the valve. Positive shut-off, "Super Closure" occurs when the plunger drive bushing forces the gland and consequently the guide sleeve to further compress the seal rings, thus creating a broad band seal against the plunger. In the open position, the plunger is retracted into the yoke, giving obstruction free flow.

The gland maintains adjustable pressure on the outer seal ring (packing)to prevent leakage to the atmosphere. Spring Loading provides compensation for wear as well expansion or contraction at all temperatures. The above attributes provide a valve suitable for the most taxing medium and operating conditions, particularly where solid particles are entrained in the flow.It is as a result widely used in the mining and PVC industries.

- Available in sizes from 1 to 24 inches and up to ASME 900#

- Adjustable spring loaded sealing - assures leak free performance open, closed or mid stroke

- Automatic packing wear compensation

- Extended plunger option

- Super Closure - when closed the actuator adds extra loading on the seal ring and packing

- Self locking stem

- Low pressure drop - high Cv 45 degree discharge pattern

- Clog free performance

- Seatless design

The Rod-Seal Valve offers numerous options:

- Valve and Piping assemblies

- Heating jackets

- Variable branch nozzle angles - (45, 60 and 90 as standard)

- Pneumatic, hydraulic or electric actuation options

- Flushing and purging connections

- Oversized main and branch flanges

- Temperature sensors in plunger head

- Zero clearance plungers

- Fail safe devices

Super Closure

Super Closure is a feature unique to the Rod-Seal Valve. It is a sealing system that uses spring loaded components to achieve two important benefits:

- Absolute positive shut off even for slurries with high particle content

- Automatic compensation for packing wear (or contraction after cool down)

The superclosure module creates additional force on the sealing ring assuring a positive seal to process and at the same time it maintains adjustable pressure on the outer packing rings, preventing leakage to atmosphere. Add to this the oversized adjustable springs which provide a high continuous sealing load to compensate for packing wear and you have a valve that outperforms all others.

This and the seatless design make the valve ideal for services that require uninterrupted flow, and absolutely no dead spaces where media can collect.