Diverter Concept

The diverter valve was developed to minimise many of the negative impacts of traditional isolation methods. In particular the use of a combination of ball or gate valves with t-pieces led to the formation of dead and slow spaces within valves and piping. This has a negative impact on both productivity and product quality.

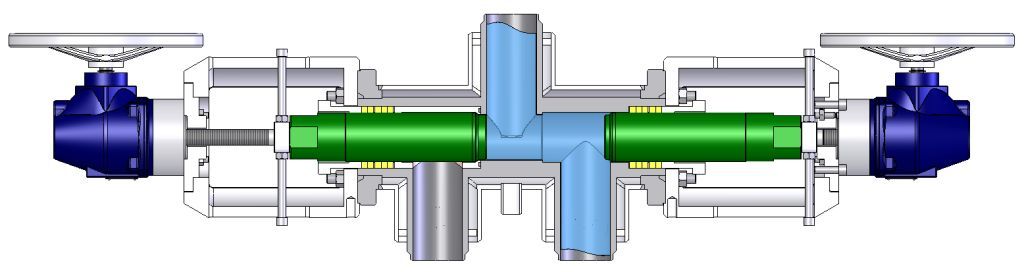

3 Way Diverter Valve

3 Way Diverter Valve The diverter valve introduced an alternative way to allow flow in one direction, whilst isolating flow to one or more other piping connections from the same take-off point. The diverter valve approach gives piping engineers the ability to route and isolate in multiple directions without creating slow or dead spaces. It has many other advantages:

- To split one large process line into many smaller lines

- To replace several isolation valves and T-pieces to eliminate back flushing of dead spaces

- To keep one line in service while maintaining another

- Switching between filters, without downtime or pressure and flow variations

- Where space does not permit larger valves or extensive piping

The Traditional Isolation Approach

The ball valve on the right hand side is open and the medium shown in blue flows from the t-piece and through the valve.When the left hand ball valve is opened, part of the residue that filled the dead spaces will either stick to the piping and thereby reduce the flow capacity and over time require the valve to be removed for maintenance. This reduces plant capacity and efficiency.

The ball valve on the left is closed but medium from the process still enters the left hand branch of the t-piece. If the medium is viscous or contains particles these will settle in the branch of the t-piece and in and around the ball of the valve. Thus the area shown in black is a deadspace.

Another perhaps even more serious side effect is when the deadspace material breaks away from the wall of the piping or valve in clumps and is carried downstream to either damage equipment or contaminate the product in batches that follow.

The Clean Alternative

The clean and more modern approach is the Fetterolf Diverter valve. The piston or Ram seals flush to the inlet body take off point in the open position.

The media can flow freely through the valve and there are no cavities, spaces or areas where sediment can stick and accumulate. The diverter valve has become a full bore extension of the pipeline whilst isolating the other branch.

Dead Space is eliminated.